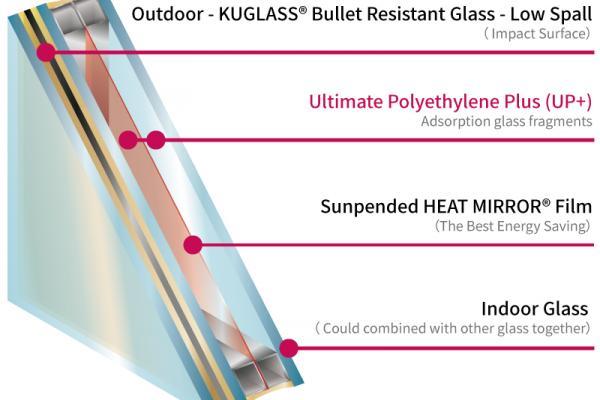

KUGLASS® Bullet Resistant Glass

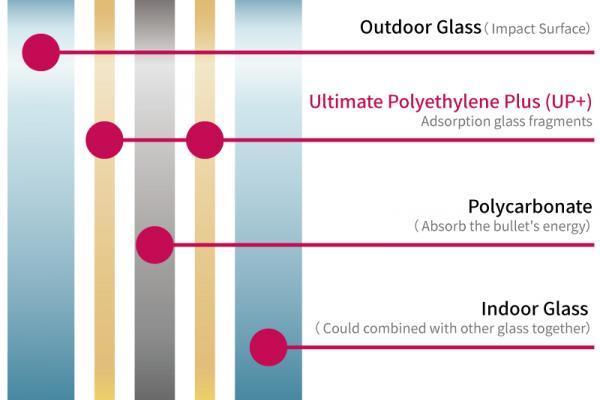

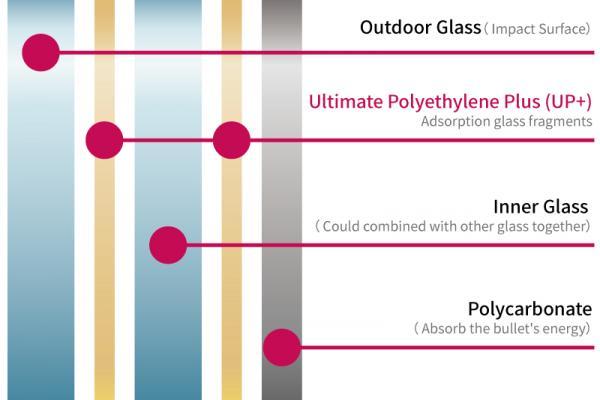

KUGLASS® Bullet Resistance Glass, the world's most stable bullet resistant glass. Using the latest Ultimate Polyethylene Plus (UP+) Technology to laminated the multi-layer of glass pane with Polycarbonate sheet by vacuum press, such manufacturing greatly improve the durability and weathering resistance, as well as the defects of yellowing and de-lamination.

The Ultimate Polyethylene Plus (UP+) Technology will grab all glass fragments, there won't be glass fragments both outside and inside

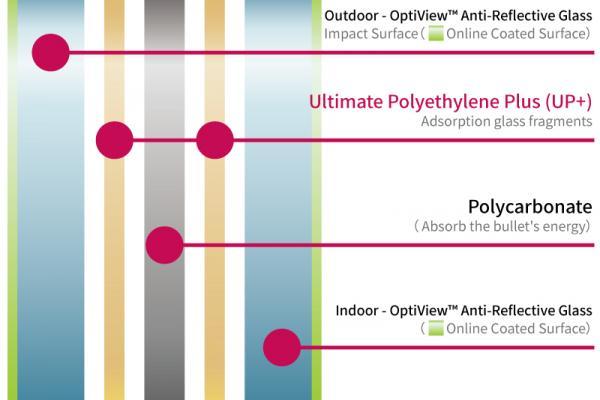

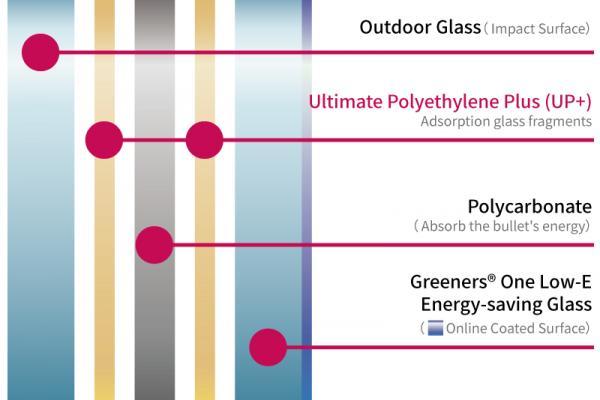

Glass Configuration

KUGLASS® Bullet Resistant Glass - Anti Reflection Model. The best choose for boutique, jewelry or silver Store, could clearly displayed products to consumers and in addition to prevent the wrong behavior from bad people.

KUGLASS® Bullet Resistant Glass - Energy Saving Model. Increase the efficiency of the heat insulating and sound insulating and so other function, meet all your need at once.

Specifications

KUGLASS® Bullet Resistant Glass provide 10 years warranty. (Excluding Artificial Damage)

| Model | MK1 | MK2 | MK3 | MK4 |

|---|---|---|---|---|

| Thickness | 13mm | 14.5mm | 19mm | 25mm |

| Configuration | 5mm + 3mm PC + 5mm | 5mm + 4.5mm PC + 5mm | 6mm + 8mm PC + 5mm | 5mm + 15mm PC + 5mm |

| Resistant Level | NIJ 0801.01 Level Ⅰ | NIJ 0801.01 Level ⅡA | NIJ 0801.01 Level Ⅱ | NIJ 0801.01 Level ⅢA |

| Impact Resistant (Joules) | 780 | 1411 | 1975 | 3330 |

| Function | Force Entry, Bullets Resistant | Force Entry, Bullets Resistant | Force Entry, Bullets Resistant | Force Entry, Bullets Resistant |

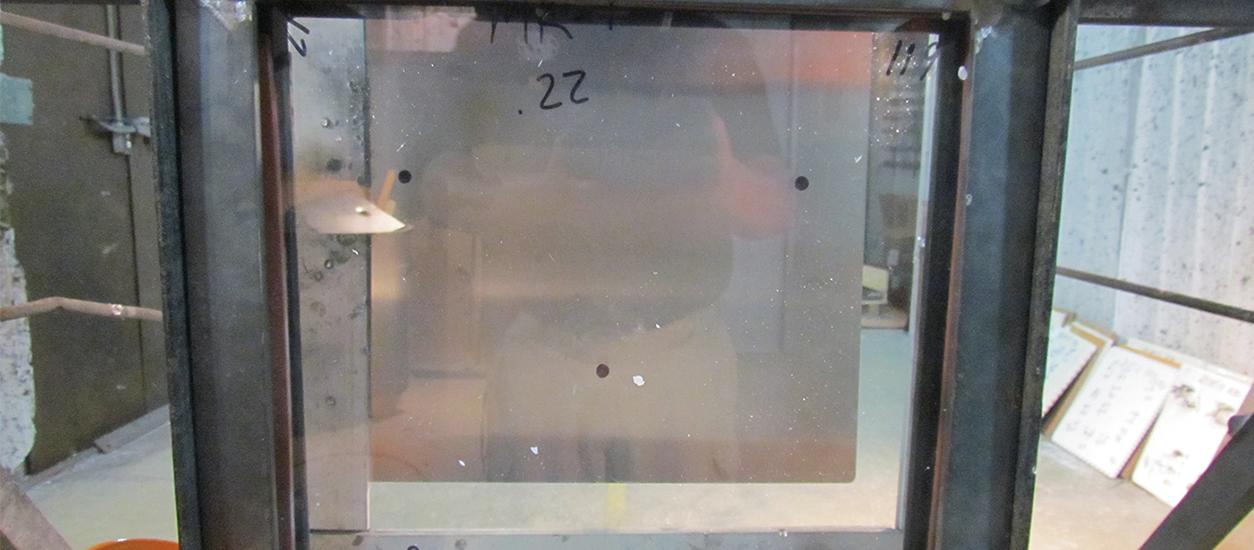

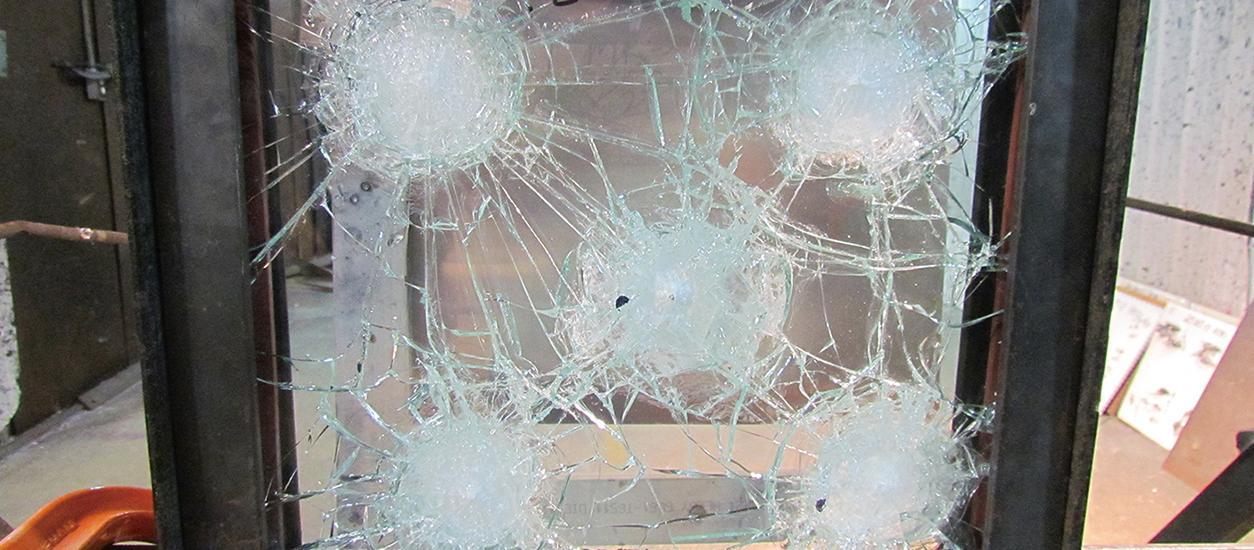

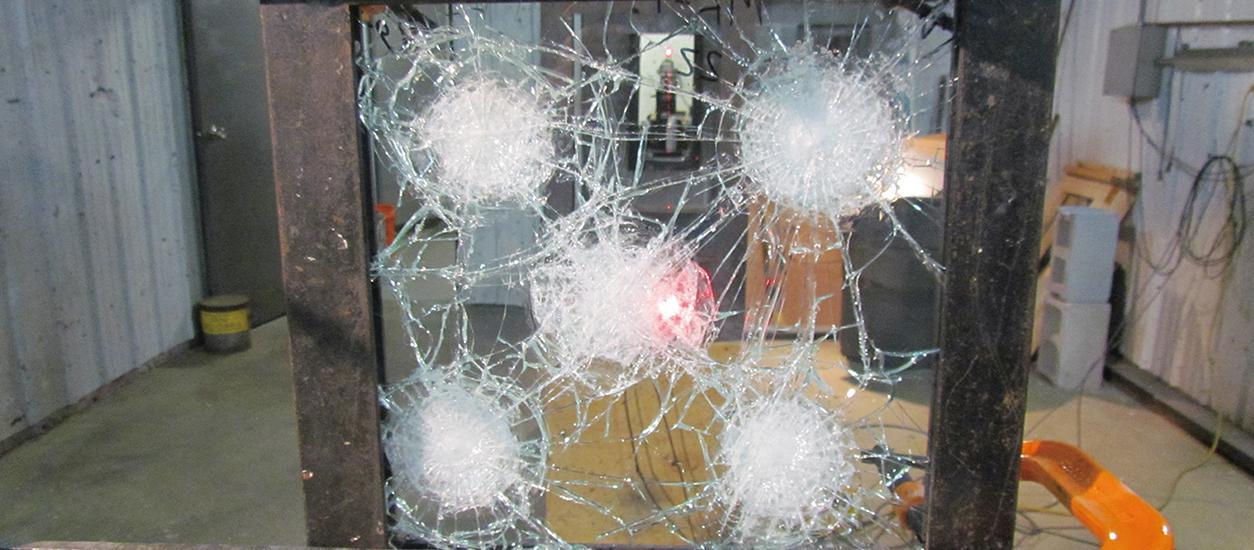

Ballistic Resistance Testing

The KUGLASS® Bullet Resistant Glass were positioned 5 meters

from the muzzle of the barrel to produce zero (0°) degree obliquity

impacts.

Penetrations were determined by visual examination of the 0.5mm

aluminum alloy witness plate, placed 15.5cm behind and parallel

to the glass to test if the bullets break through the glass and hit the

aluminum plate.

Worldwide Certificate

Passed the H.P. White Laboratory ballistic resistance testing, pass the Armaments Bureau, TAIWAN MND bullets resistance test and pass SGS weatherability test.

Weatherability Database

Pass SGS weatherability test.

| Properties | Unit | KUGLASS® | Test Method | ||

|---|---|---|---|---|---|

| Physical Property | Density | g/cm³ | 0.95 | ASTM D1505 | |

| UP+ Film Thickness | mm | 0.4 / 0.6 / 0.8 | |||

| Glass transition temperature,Tg | ℃ | -28 | DSC | ||

| Melting temperature | ℃ | 72 | DSC | ||

| Water absorption*1 | % | <0.1 | |||

| Mechanical Property | Tensile strength | kg/cm² | >100 | ASTM D638 | |

| Elongation rate | % | <1000 | ASTM D638 | ||

| Ball drop test (1040g steel ball, 1.2m height)temperature,Tg | Qualified | JIS R 3205 | |||

| Impact test (45kg, 48cm height) | Qualified | JIS R 3205 | |||

| Optical Property | Visible light transmittance*2 | % | >85 | ASTM D1003 | |

| UV cut wavelength*2 | nm | 370 | ASTM D1003 | ||

| Haze*2 | % | <1 | ASTM D1003 | ||

| Weather Durability | Boil test(100℃, 2hr) | Appearance | No change | JIS R 3205 | |

| Transmittance | % | ||||

| Haze | % | ||||

| UV test 15kW*hr(280~385nm) +5kW*hr(280~320nm) | Appearance | No change | IEC 61215 | ||

| Transmittance | % | ||||

| Haze | % | ||||

| Temperature cycling test (-40℃,10min~85℃,10min)x 340 cycle | Appearance | No change | IEC 61215 | ||

| Transmittance | % | ||||

| Haze | % | ||||

| Damp heat test (50℃,RH95%) x 4 Weeks | Appearance | No change | ISO 12543 | ||

| Transmittance | % | ||||

| Haze | % | ||||

| Immersion test (Room temperature) | |||||

| 1. Water (12 Months) | Appearance | No change | KUGLASS® | ||

| Transmittance | % | ||||

| 2. Saline water 5% NaCl (12 Months) | Appearance | No change | KUGLASS® | ||

| Transmittance | % | ||||

| 3. Acid solution (pH=4.3) (12 Months) | Appearance | No change | KUGLASS® | ||

| Transmittance | % | ||||

| *1: 85℃,RH85%,6hr | |||||

| *2: (3+3)mm clear glass + 0.4mm film | |||||

Laminated Technology Comparison

KUGLASS® using the latest adhesive thin film technology, Ultimate Polyethylene Plus (UP +). This technology has excellent bonding strength to each material.

| Bonding Strength | EVA | PVB | KUGLASS®(UP+) |

|---|---|---|---|

| Glass | 1.8 | 1.3 | 6.1 |

| PET Film | 1.9 | 0.1 | 5.1 |

| PC Sheet | 1.1 | -- | 2.7 |

| Stainless Steel | 0.2 | -- | 1.8 |

Contact US

Tel:(02) 2930-0093 / Fax:(02) 2930-0072

1F., No. 43, Sec. 5, Xinhai Rd., Wenshan Dist., Taipei City 116, Taiwan

中文(繁體.台灣)

中文(繁體.台灣)